Custom PCB Design vs. Off-the-shelf Boards: Which Is Right for Your Product?

Aug 13, 2025 | 2 min read

A common question we hear from startups, product owners, and even seasoned engineering teams is this: Do we need a custom PCB design, or will an off-the-shelf board work just fine?

What’s great about this question is that it’s not just a technical one, it’s also a business one. There are multiple factors to consider, and the wrong choice can cost you time and money. So, it’s important to get it right!

In this article, I’ll explain the key differences between custom and off-the-shelf boards to help you decide which path makes the most sense based on your product’s needs, timeline, and budget.

You’ll find answers to questions like:

- What’s the difference between off-the-shelf and custom boards?

- What are the pros and cons of each?

- When should you choose custom board design vs. off-the-shelf?

- How do costs compare?

- What are some common board strategy mistakes to avoid?

- How to decide which is right for your specific product

What’s the Difference Between Off-the-shelf and Custom PCBs?

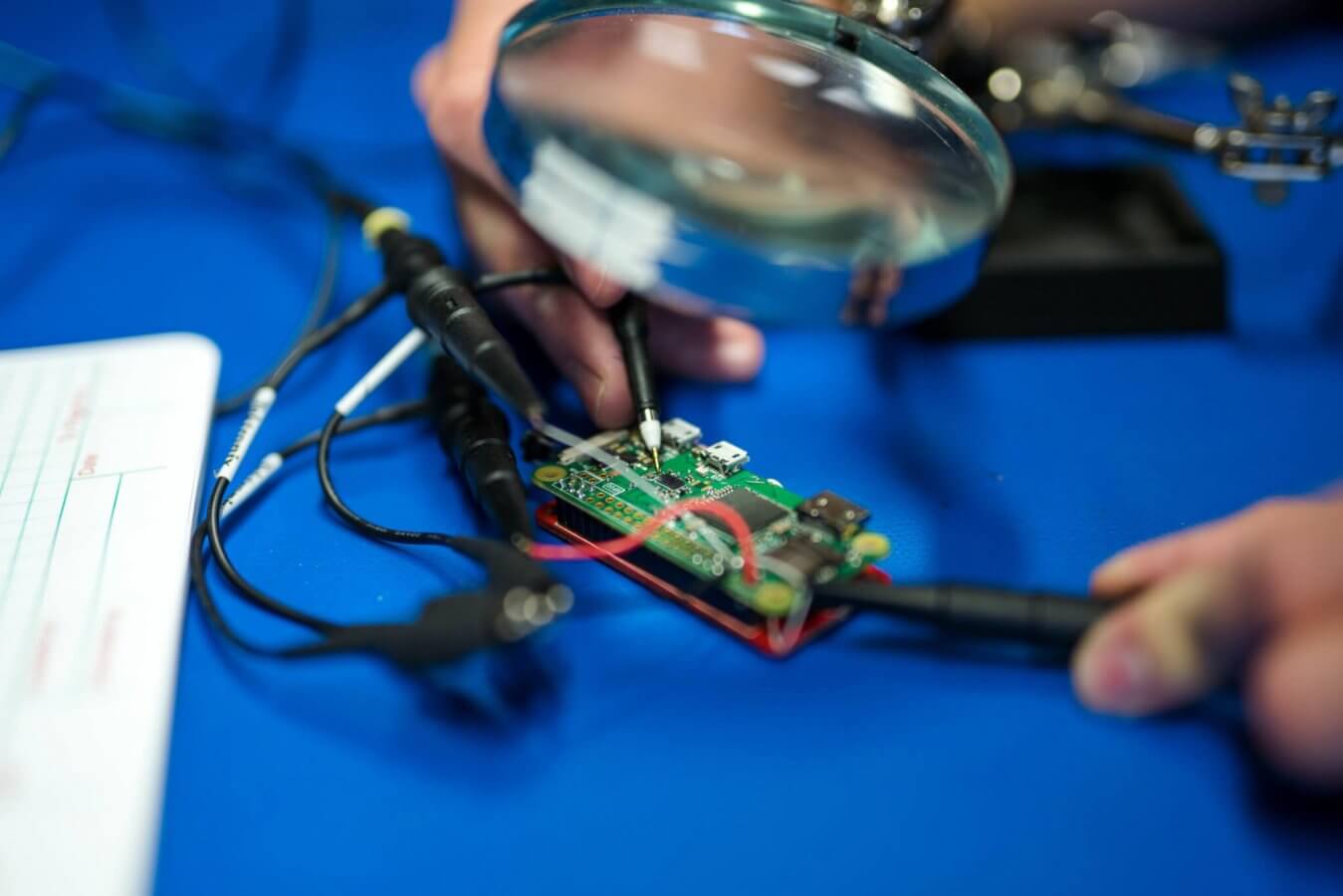

Off-the-shelf boards feature a fixed printed circuit board (PCB) layout and pre-selected components assembled into a finished PCB. They are purchased as-is and are commonly found in development kits (e.g., Arduino, Raspberry Pi) or as standalone modules from vendors. Since these products are mass-produced, their availability depends on vendor inventory, which can be affected by supply fluctuations and may lead to extended lead times.

Custom boards are designed with a tailored PCB layout and carefully selected components to meet specific mechanical, electrical, and performance requirements. This customization can include layout optimization, component sourcing, board geometry, thermal management, and more. Development is done in close collaboration with a design engineer, ensuring the chosen components and layout address both functional needs and market supply constraints. In many cases, the design engineer will also assist in selecting a contract manufacturer suited to your production scale—whether low, medium, or high volume.

Custom PCB Design vs. Off-the-shelf Board Pros and Cons

| Feature | Custom Board | Off-the-shelf Board |

|---|---|---|

| Cost | HIgher upfront design cost, lower per-unit at scale | Lower upfront cost, higher per-unit over time |

| Performance | Optimized for your product | General purpose |

| Size and shape | Fully customizable | Fixed dimensions and layout |

| Speed | Slower to start | Faster to prototype |

| Scalability | Ideal for production | Best for prototyping or low-volume |

| Support | Requires electronics engineering expertise | Supported by a wide community and documentation |

When to Use a Custom PCB Design

A custom board design is probably the best option if your product requires:

- Tight mechanical integration (e.g., wearables or medical devices)

- Low power consumption

- High reliability or environmental durability

- High-volume production with cost efficiency over time

- Unique form factors

A few common use cases I can think of are:

- IoT products with specific wireless protocols, power budgets, or shielding needs

- Automotive or aerospace components with extreme vibration and temperature requirements

- Handheld devices needing to fit into sleek, branded enclosures

When to Use an Off-the-shelf Board Design

Commercially available boards are usually the smartest choice when:

- You’re building a proof of concept

- Time-to-market is tight

- Budget is limited

- Your product isn’t highly customized

Because they’re pre-built and often plug-and-play, you can test functionality quickly and iterate before investing in custom design. Some companies even launch V1 of their product using standard boards to validate demand.

Just be cautious, because what works for prototyping might not scale the best long-term. In fact, to transition from a prototype off the shelf board to a custom one for production, you may end up tossing out a lot of your initial development work! Similarly, standard boards are not designed to meet certification requirements; therefore, it is important to consider the needs and regulations of your target market.

Cost Comparison Between Custom and Off-the-shelf PCBs

Let’s talk about money because this is where a lot of confusion happens.

When comparing costs, it’s important to think of upfront design costs and long-term production costs.

- For custom boards, you should expect to spend anywhere from $5,000 to $150,000 in non-recurring engineering costs for multiple iterations of the board, depending on the complexity. But once you’re in production, unit costs can drop significantly.

- For off-the-shelf boards, you’ll save on upfront engineering, but you could pay $10 – $40 per unit or more during production — sometimes for capabilities you don’t need.

And for both of these, remember that you’ll need to spend additional time and money to develop your custom code and get your product through regulatory testing once the hardware is ready! If you plan to build more than a few hundred units, you’ll find that a custom design can pay for itself faster than you’d think.

Common Mistakes When Deciding Between Board Types

These are some oversights I see with customers most often:

- Overengineering too early: Spending time and money on a perfect board before the product is validated.

- Underestimating complexity: Using standard boards without realizing they’ll limit power, thermal, or performance down the road.

- Forgetting about compliance: FCC testing and other regulatory compliance (CE, UL, etc.) is an important part of making your design production ready. Choosing a standard board with the correct regulatory marks can expedite your approval process, but sometimes a custom board will provide the smoother path.

- Incorrectly understanding scalability: Use of a standard board while you prototype locks you into certain design decisions should you decide you need to switch to a custom board for production. This can lead to cost, availability, and other tradeoffs – or it can lead to rework as you are forced to replace the features you developed on the standard board with new components in the custom design to achieve your production targets.

How to Decide Which PCB Option Is Right for You

Use this basic framework to make an educated guess.

| Criteria | Custom Board | Off-the-shelf Board |

|---|---|---|

| Budget | Higher upfront budget | Lower upfront budget |

| Timeline | Flexible/long-term | Need it fast |

| Volume | High-volume | Low-volume or test market |

| Features | Unique feature needs | Features available in a standard board |

| Form factor | Compact or custom enclosures | Generic or open designs |

| Product maturity | Ready to scale | Still validating market fit |

You might also use this simple decision-making checklist:

- Do you need a unique size, shape, or feature set?

- Are you going to produce more than 500 units this year (consider this number based on your price point, industry, etc.)?

- Does your product require high reliability or integration?

If yes to two or more: the custom board design may be worth the upfront investment.

If no: the off-the-shelf board might get you where you need to go, at least for now.

Next Steps for Your Design Team

As you move forward, just remember that choosing between a custom board and an off-the-shelf board isn’t just about specs. It’s about where your product is headed. Make sure to consider all the factors — technical and business — before making your decision.

If you want a second opinion on which approach makes sense for your product, my team can help. We work with customers of all sizes a

Written By:

Anton Petrenko

Electronics Engineer

DISHER Newsletter

Sign up to receive articles and insights, delivered monthly.

Schedule a no-committment project call

Reach out to discuss your project to find out if DISHER could be a good fit for you.